our technical means

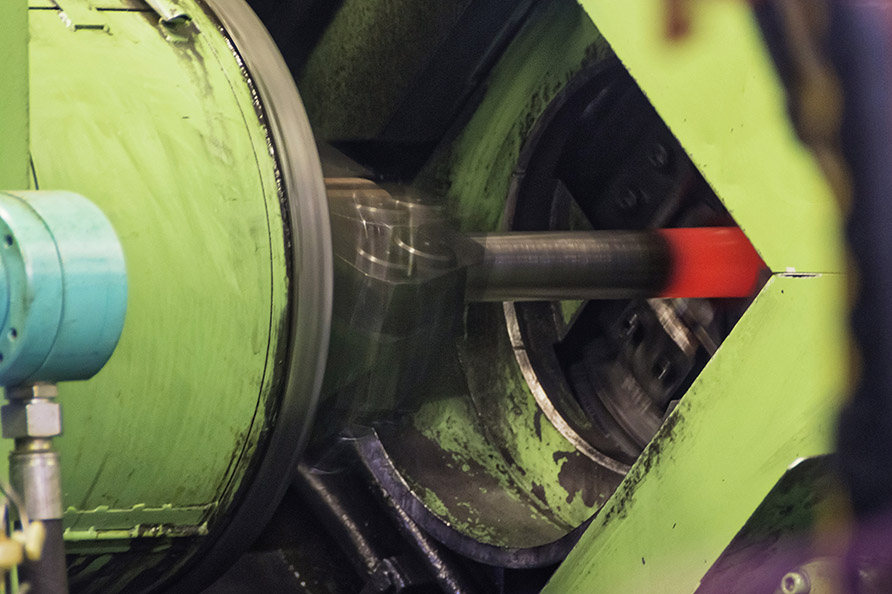

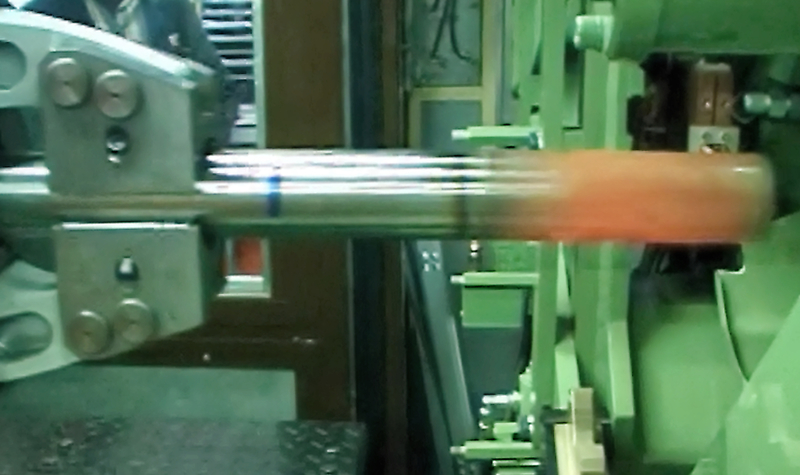

Hot swaging

Thanks to more than half a century of industrial know-how in aeronautics, for our customers, our experience is the best guarantee of the proficiency of our processes.

Swaging is our core business.

This forging process produces rods with undisputed mechanical characteristics

by deforming materials such as aluminum, titanium, stainless steel, etc. …

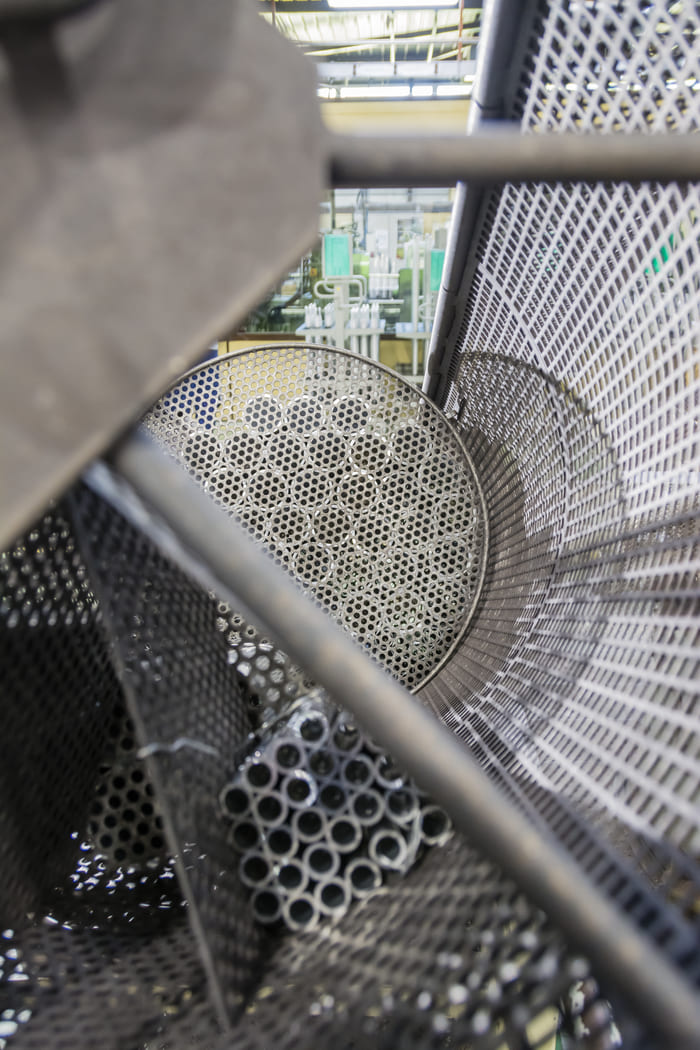

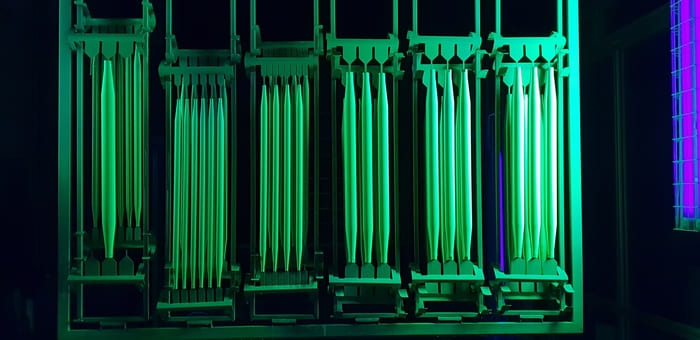

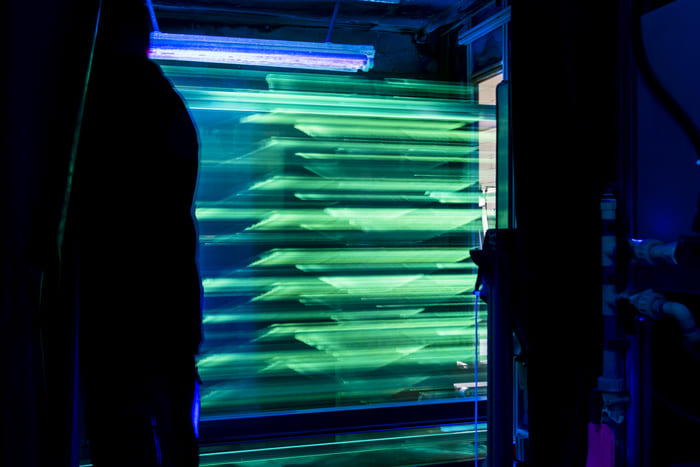

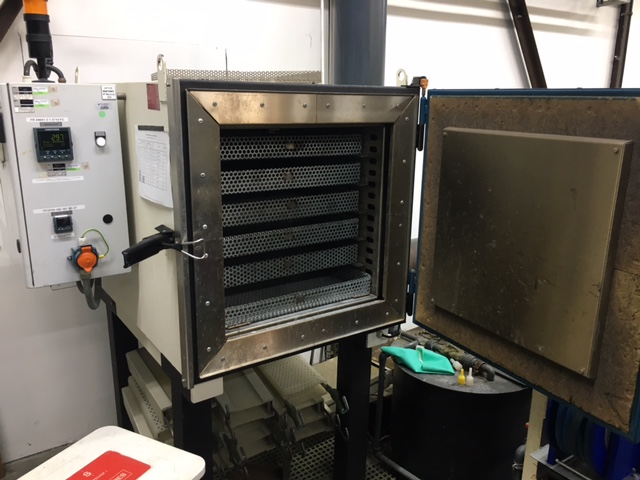

Heat treatments

The associated heat treatment processes ensure that the material’s mechanical properties comply with the specifications we receive from the customers.

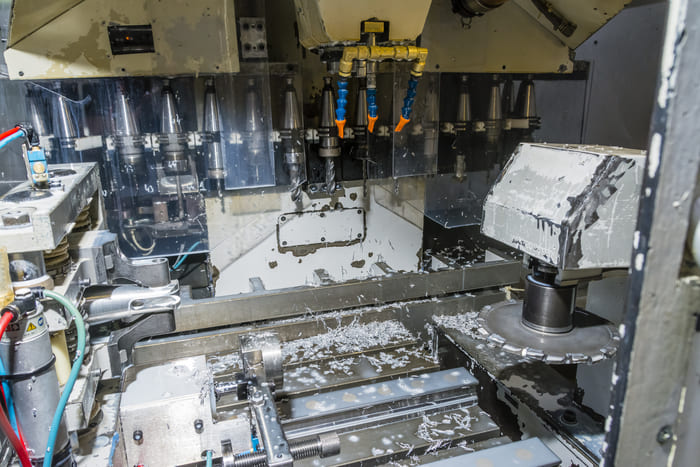

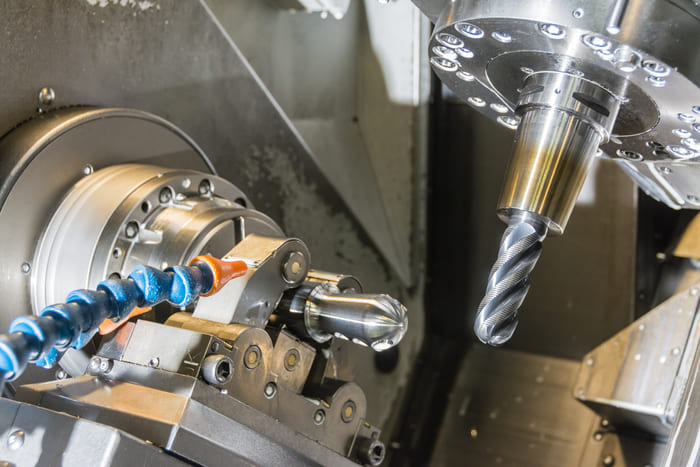

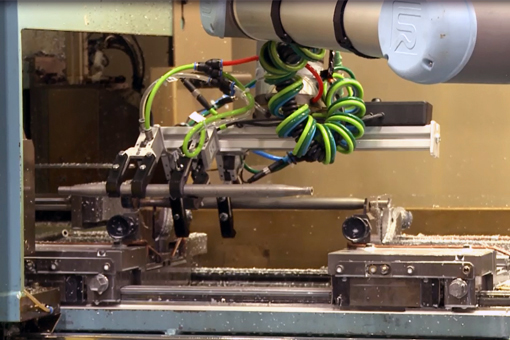

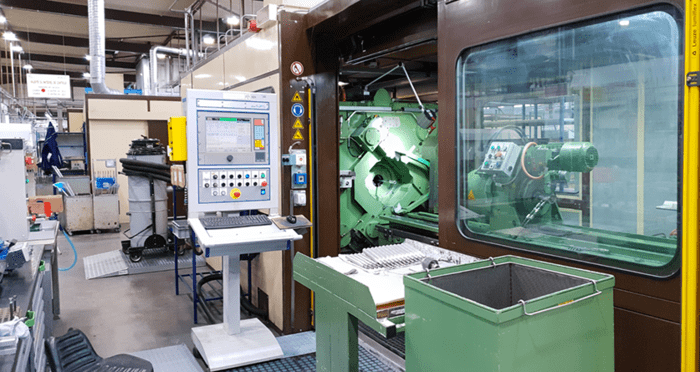

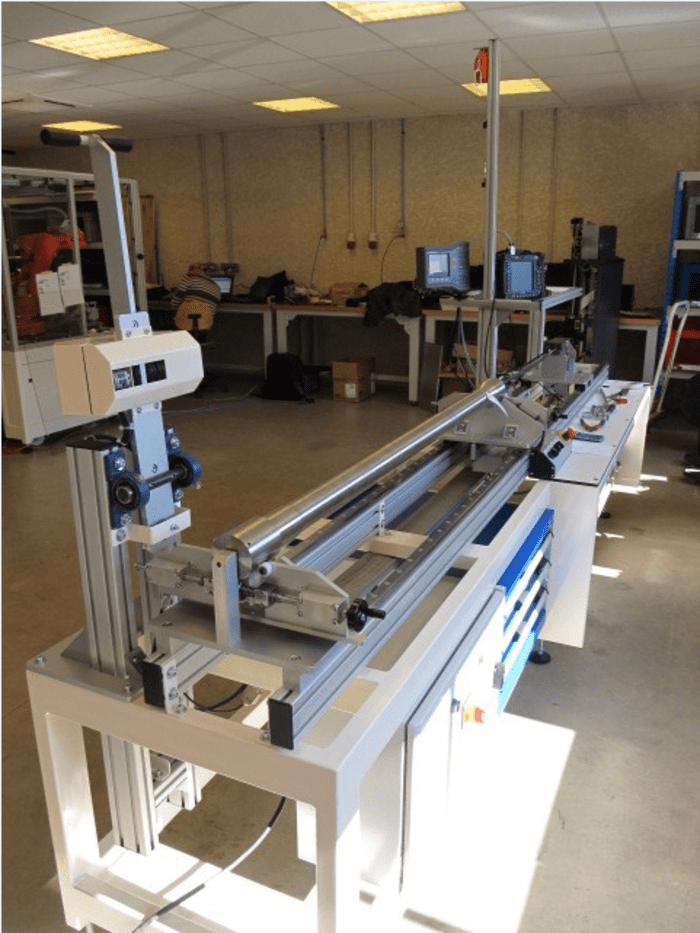

Machining

High-performance machining facilities are available to our customers to comply with their highest requirements, particularly for the space sector.

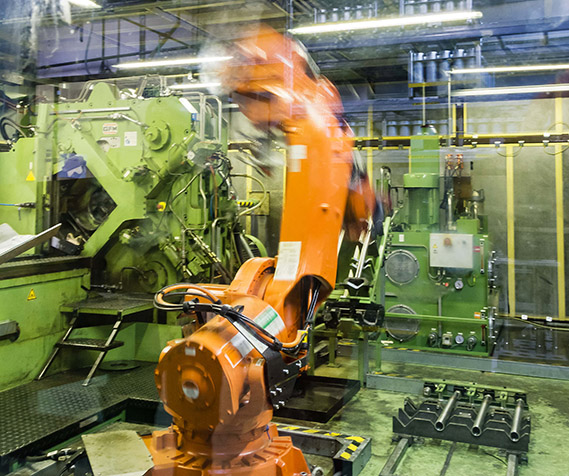

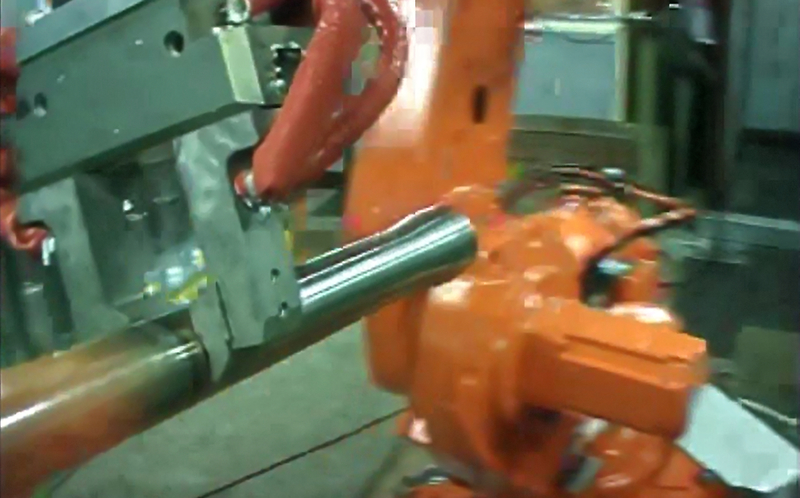

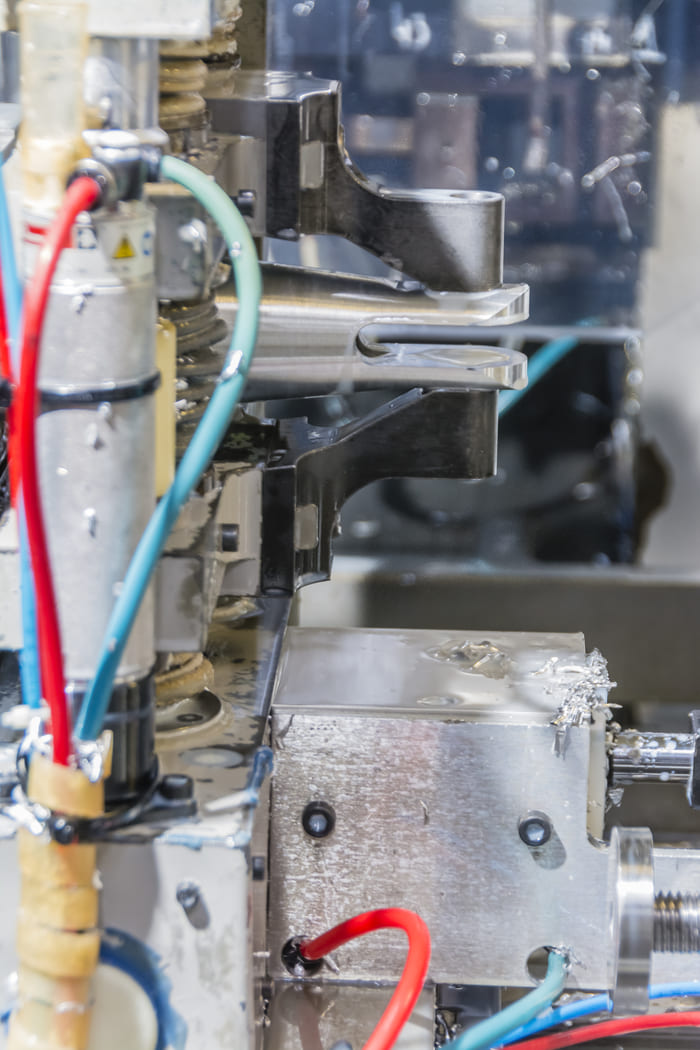

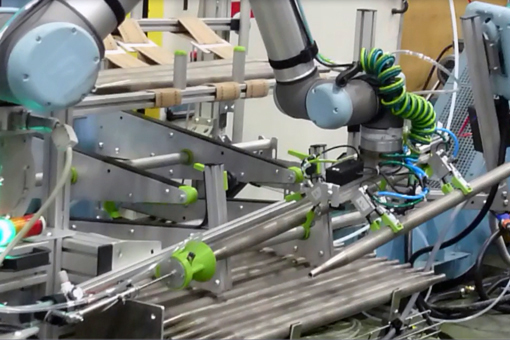

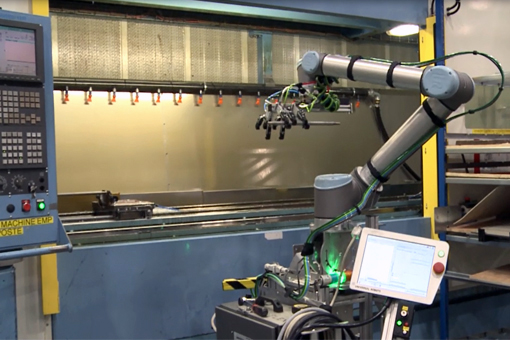

Industrial means & Innovation/Industry 4.0

These industrial means, whether specific and manual for adjustment, or with robot assistance (Industry 4.0), allow us to meet all our customers’ needs, from the most specific to the most generic.

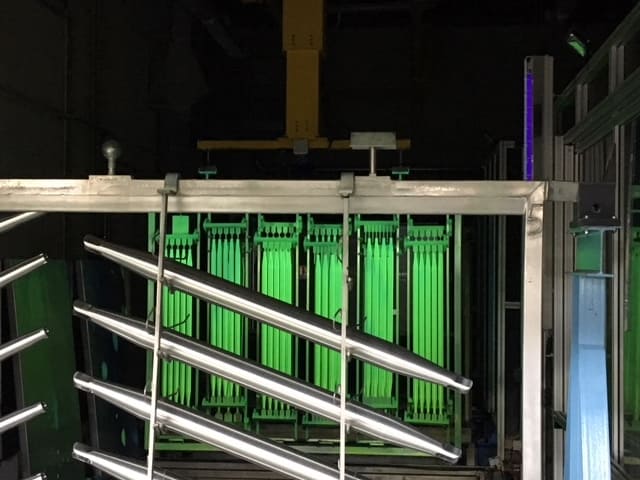

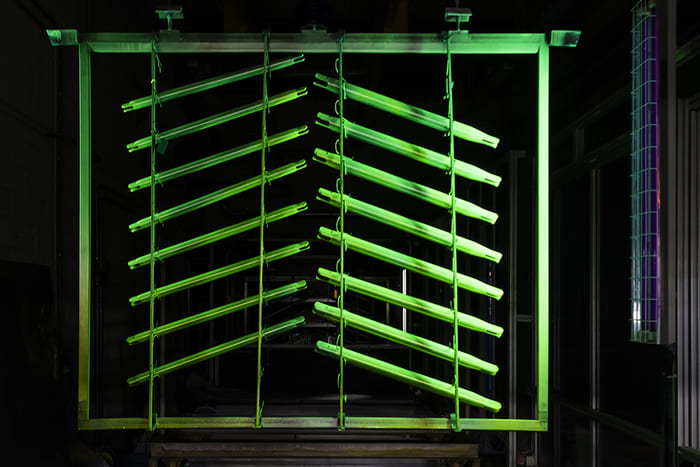

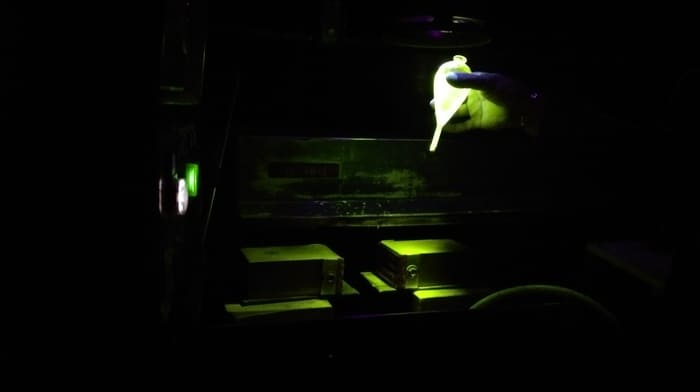

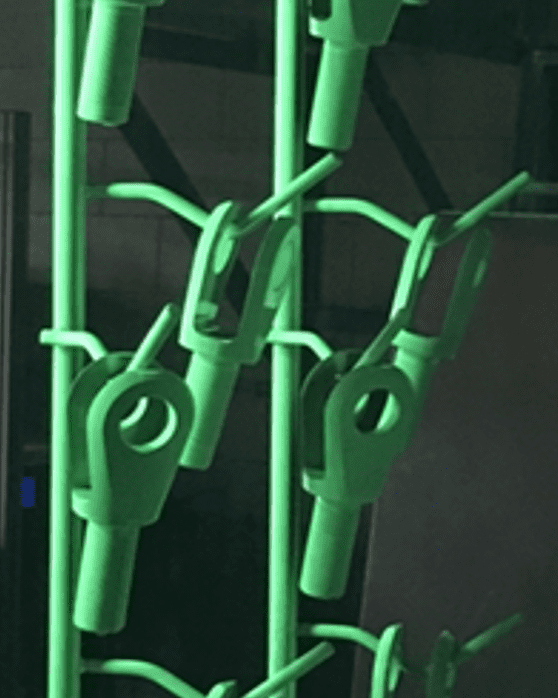

These methods of control (non-destructive: FPI fluorescent penetrant inspection, MPI magnetic penetrant inspection, eddy currents, ultrasonic testing) and surface treatments (chemical and paint) ensure the adequacy of our processes with NADCAP standards.

watch the video

Performance

Performances of our processes are recognized by the leading aircraft manufacturers, such as the Airbus group, which has already honored us with several awards:

Machines

Our production capacity is organized according to a full integration model.

We have a wide variety of equipment in our factory, from the most traditional to the most innovative machines.

- Swaging machines (hot & cold)

- Automated and robotic machining centers

- Heat treatment furnaces

- NACAP equipment for FPI and MPI

- Eddy current facility

- Surface treatment

- Automated painting shop